Understanding the Importance of Hydraulic Balls in Modern Industries

The phrase "hydraulic ball" has been gaining traction in the engineering and industrial sectors, signifying a pivotal component in fluid control systems. As the demand for efficient and reliable machinery grows across various industries, understanding hydraulic balls becomes essential for businesses looking to optimize their operations. In this comprehensive guide, we will delve into the intricacies of hydraulic balls, their applications, benefits, and how they can transform your business operations.

1. What is a Hydraulic Ball?

A hydraulic ball is a crucial element in hydraulic systems, typically serving as a valve or actuator that controls the flow of fluid through a pipeline. These balls are designed to regulate the start, stop, or flow rate of liquids under high pressure. They come in various sizes and materials, tailored to meet the specific needs of different applications.

1.1 The Design of Hydraulic Balls

Hydraulic balls are generally made from durable materials such as stainless steel, brass, or high-density plastics. Their spherical shape allows for smooth and unobstructed flow of liquids, making them highly efficient. The innovative design is crucial for minimizing friction loss and ensuring reliable operation even under extreme conditions.

2. Key Applications of Hydraulic Balls

The versatility of hydraulic balls makes them suitable for a multitude of applications across different industries. Some of the prominent sectors utilizing these components include:

- Agriculture: Used in irrigation and spray systems for efficient water management.

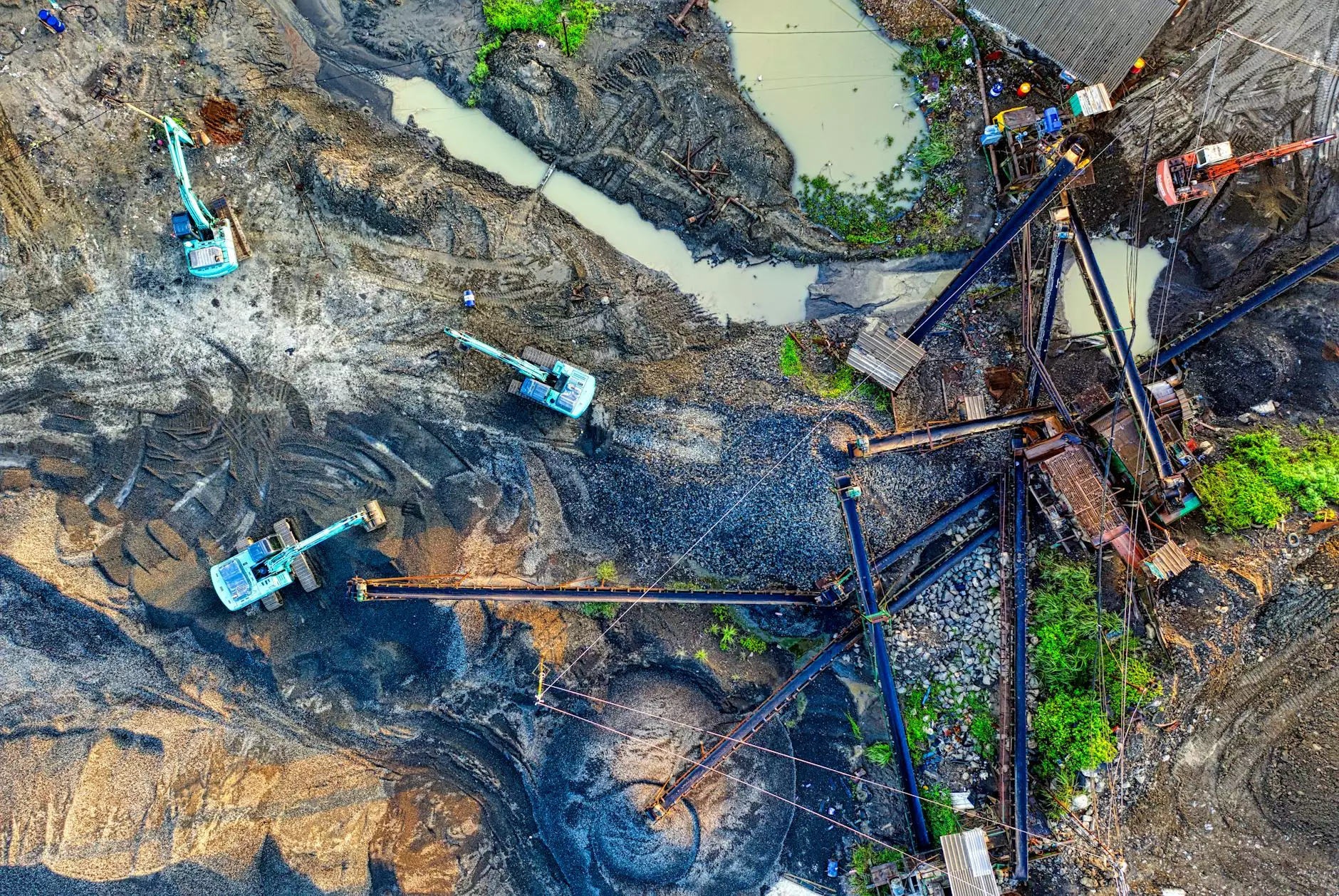

- Construction: Integral in hydraulic machinery, including excavators and bulldozers, enabling precise control of the equipment.

- Manufacturing: Hydraulic balls are pivotal in automated assembly lines, ensuring seamless operation of machinery.

- Automotive: Essential in vehicle braking systems and power steering applications.

- Oil and Gas: Employed in drilling systems and flow control mechanisms, facilitating safe and effective extraction processes.

3. Advantages of Using Hydraulic Balls

Implementing hydraulic balls in your systems offers numerous benefits. Here are some essential advantages:

- High Efficiency: Hydraulic balls allow for minimal resistance to fluid flow, resulting in enhanced system efficiency.

- Durability: Constructed from robust materials, hydraulic balls are designed to withstand harsh environments and high-pressure conditions.

- Cost-Effectiveness: Their longevity and efficiency lead to reduced maintenance costs and prolonged service life of equipment.

- Versatility: They can be used in various applications, making them a flexible choice for numerous industries.

- Quick Response Time: Hydraulic balls enable prompt operational responses, enhancing overall productivity.

4. Choosing the Right Hydraulic Ball for Your Needs

Selecting the appropriate hydraulic ball for your specific application is crucial. Here are some factors to consider:

- Size: Ensure the hydraulic ball fits seamlessly into your existing system.

- Material: Choose a material that can withstand the corrosive nature of the fluids involved.

- Pressure Rating: Consider the maximum pressure your system will encounter to select a hydraulic ball that can handle the demands.

- Seal Type: Evaluate the seal type for compatibility with your hydraulic system to prevent leaks.

5. Maintenance Tips for Hydraulic Balls

To ensure longevity and optimal performance of hydraulic balls, regular maintenance is essential. Here are some practical tips:

- Regular Inspections: Schedule routine checks to identify any signs of wear or damage.

- Fluid Quality: Monitor and maintain the quality of hydraulic fluids, as contaminants can lead to premature failure.

- Operational Checks: Test the functionality of hydraulic balls to ensure they operate smoothly without any obstruction.

- Replace Seals: Regularly check and replace seals as required to avoid leaks and ensure efficiency.

6. The Future of Hydraulic Ball Technology

The future looks promising for hydraulic ball technology. Advancements in materials science and engineering are leading to the development of even more efficient and durable components. Innovations include:

- Smart Hydraulic Balls: Incorporating IoT technology for real-time monitoring and adaptive control.

- Eco-Friendly Materials: Researching sustainable materials for environmentally friendly hydraulic systems.

- Enhanced Performance: Ongoing development to provide higher pressure capabilities and improved flow characteristics.

7. Why Choose Fitsch.cn for Your Hydraulic Ball Needs

For businesses looking for reliable fittings for sale, Fitsch.cn stands out as a leading supplier of hydraulic balls and related components. Here’s what sets us apart:

- Extensive Product Range: We offer a wide selection of hydraulic balls tailored to various applications and industry needs.

- Quality Assurance: Our products undergo rigorous testing to meet international standards, ensuring reliability and safety.

- Expert Support: Our team of experts is ready to assist you in choosing the right hydraulic ball and offer insights into installation and maintenance.

- Competitive Pricing: We provide high-quality products at competitive prices, helping you achieve cost savings.

- Customer Satisfaction: Our commitment to service ensures that each client receives personalized attention and support.

8. Conclusion: The Essential Role of Hydraulic Balls

In summary, hydraulic balls play an essential role in various industrial applications, offering efficiency and reliability. As technology progresses, the capabilities of hydraulic balls will continue to expand, solidifying their importance in fluid control systems. By choosing Fitsch.cn for your hydraulic ball and fittings needs, you’re investing in quality, innovation, and unmatched service. Embrace the future and enhance your operational efficiency today!